Here are some sewing tips to keep in mind when working with BioThane® coated webbing.

https://www.youtube.com/embed/cUFyx0JF5LY?rel=0 https://www.youtube.com/embed/ZXRaGChLsRM?rel=0 https://www.youtube.com/embed/9KQZFlQb-iI?rel=0 https://www.youtube.com/embed/exyrEj-7QGI?rel=0 https://www.youtube.com/embed/PJkR4seSwPA?rel=0Heavy Material Sewing Machine

- Typically, machines used for sewing heavy materials such as leather can handle BioThane® belting.

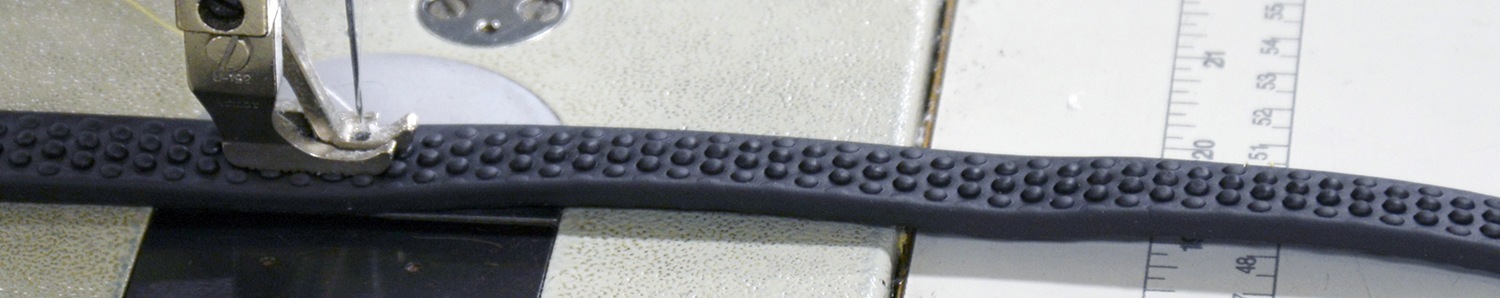

- For continuous feed, use a walking foot or compound-feed sewing machine with a toothed plate.

Thread Tension and Lubrication

- Maintain close control over thread tension and lubrication.

- Thread tension must be higher than for sewing leather.

- Only lubricated or bonded thread is recommended.

- Ready-wound bobbins will keep thread tension consistent.

- Changing gearbox settings to reduce speed and increase power produces a tighter, more uniform stitch pattern.

- Spraying thread with silicone improves sewing.

- Either “MB” or “GM” treatment also helps performance.

- Most commonly used thread weights are #69, #92 and #99.

Needles: Diamond Point or Standard

- Use needles with a sharp point.

- Diamond point and standard needles will provide the best results.

- Do NOT use Teflon coated needles. They have not performed well on our belting.

- Choose needles that have grooves twice the size of the thread being used so the thread is forced through the stitch.

- The maximum recommended stitch pattern is 6 stitches per inch.

- Sewing BioThane® belting tends to dull any needle, so be sure to replace needles before they lose their effectiveness.

Still have questions about sewing BioThane coated webbing?